Fibre Laser Cleaning

What is fibre laser cleaning?

Laser cleaning is an innovative non-contact cleaning process utilising laser beams to free a surface of contaminants such as Rust, oil, oxidation, paint, grease, and other surface coatings. The origins of laser cleaning date back to the 1980s, when lasers were used to clean delicate surfaces within the aerospace industry. Since then laser cleaning technology has undergone continuous refinement, finding applications across a wide spectrum of industries including Marine, Aerospace, Automotive, Manufacturing, Fabrication, Heritage conservation, NDT testing, Paint & graffiti removal, Stone & statue cleaning, and many more.

In recent years, laser cleaning has surged in popularity owing to its efficacy in cleaning and its non damaging effect on the substrate.

How does laser cleaning work?

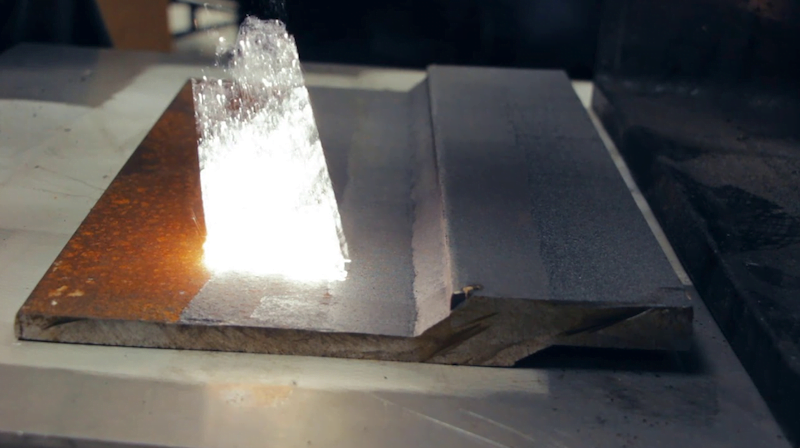

Laser cleaning works by sending nanosecond-length pulses of laser light towards surface contaminants, vaporising them into dust and fumes through laser ablation. When the laser beam hits the surface, part of its energy is absorbed by the metal surface, and the rest is reflected. Contaminants are ejected when they have absorbed enough energy to reach their ablation threshold.

With the right laser settings and equipment, laser cleaning is unmatched in its ability to clean all the way to the bare metal of your product without damaging the substrate underneath.

Call us on

What are the advantages of laser cleaning?

- No waste & No clean-up

Unlike conventional abrasive methods, there is no need to dispose of the removed material. There is very little residue and any residue that is created is easily removed using a low-suction air filtration system. - No consumables

Traditional abrasive cleaning methods either require large amounts of costly consumables or special chambers to carry out the cleaning process. Laser cleaning is completely self-contained and the only utility required is electricity. - Completely non abrasive

Laser cleaning is completely non-abrasive and is an excellent choice for applications where a tight tolerance is required after the cleaning process has been completed. In general laser cleaning will remove only the surface contaminants on the substrate and once removed, the process is self terminating meaning no damage or imperfections on the surface material will occur.

Reviews

"Just had our outboard and SIB serviced ready for the summer. Great service, very pleased."

-Lizzy C